Article Database

Circular

June 26, 1972

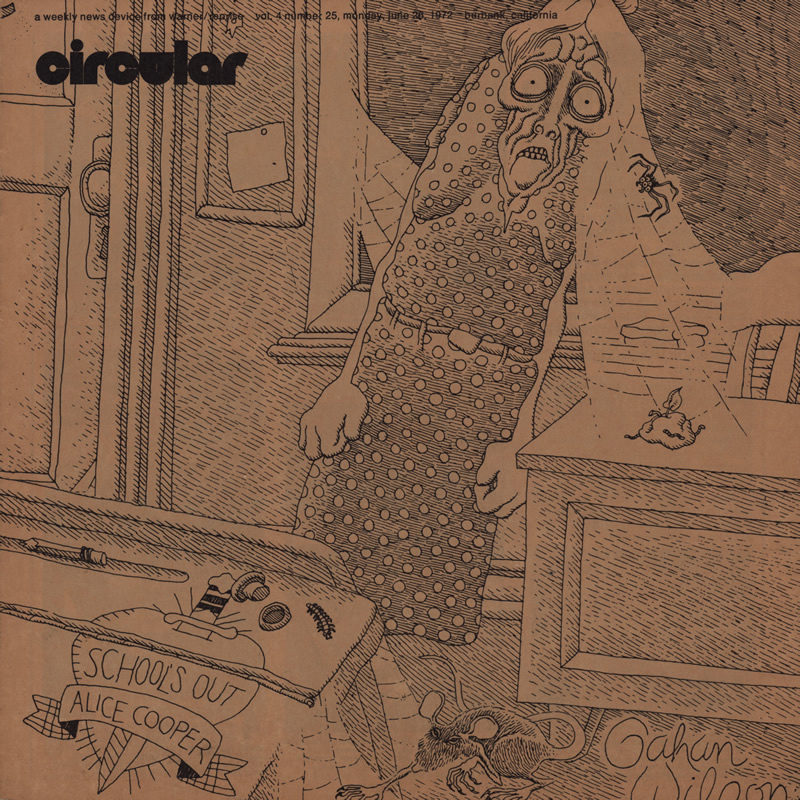

What Makes Alice Run?

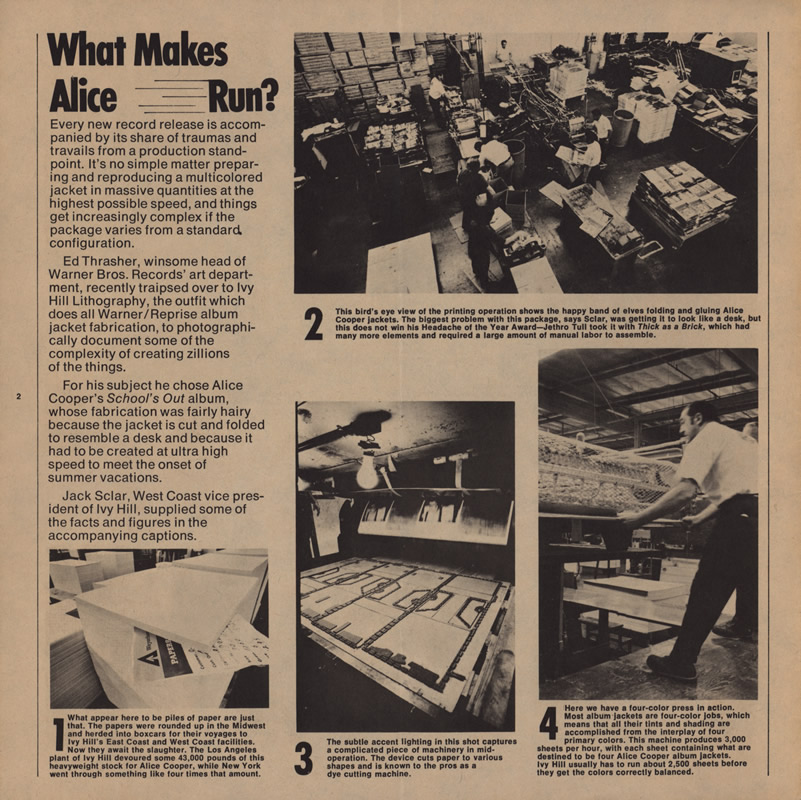

Every new record release is accompanied by its share of traumas and travails from a production stand point. It's no simple matter preparing and reproducing a multicolored jacket in massive quantities at the highest possible speed, and things get increasingly complex if the package varies from a standard configuration.

Ed Thrasher, winsome head of Warner Bros. Records' art department, recently traipsed over to Ivy Hill Lithography, the outfit which does all Warner/Reprise album jacket fabrication, to photographically document some of the complexity of creating zillions of the things.

For his subject he chose Alice Cooper's School's Out album, whose fabrication was fairly hairy because the jacket is cut and folded to resemble a desk and because it had to be created at ultra high speed to meet the onset of summer vacations.

Jack Sclar, West Coast vice president of Ivy Hill, supplied some of the facts and figures in the accompanying captions

1. What appears here to be piles of paper are just that. THe papers were rounded up in the Midwest and herded into boxcars for their voyages to Ivy Hill's East Coast and West Coast facilities. Now they await the slaughter. The Los Angeles plant of Ivy Hill devoured some 43,000 pounds of this heavyweight stock for Alice Cooper, while New York went through something like four times that amount.

2. The bird's eye view of the printing operation shows the happy band of elves folding and gluing Alice Cooper jackets. The biggest problem with this package, says Sclar, was getting it to look like a desk, but this does not win his Headache of the Year Award — Jethro Tull took it with Thick as a Brick, which had many more elements and required a large amount of labor to assemble.

3. The subtle accent of lighting in this shoot captures a complicated piece of machinery in mid-operation. The device cuts paper to various shapes and is known to the pros as a die cutting machine.

4. Here we have a four-color press in action. Most album jackets are four-color jobs, which means that all their tints and shading are accomplished from the interplay of four primary colors. This machine produces 3,000 sheets per hour, with each sheet containing what are destined to be four Alice Cooper album jackets. Ivy Hill usually has to run about 2,500 sheets before they get the colors correctly balanced.

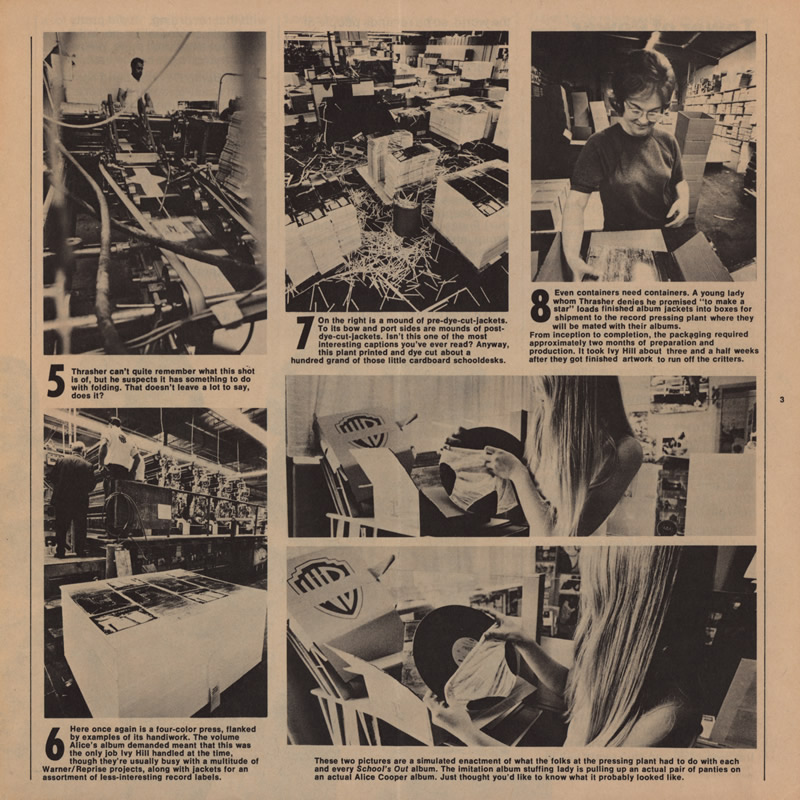

5. Thrasher can't quite remember what this shot is of, but he suspects it has something to do with folding. That doesn't leave a lot to say, does it?

6. Here once again is a four-color press, flanked by examples of its handiwork. The volume Alice's album demanded meant that this was the only job Ivy Hill handled at the time, though they're usually busy with multitude of Warner/Reprise projects, along with jackets for an assortment of less-interesting record labels.

7. On the right is a mound of pre-dye-cut-jackets. To its bow and port sides are mounds of post-dye-cut-jackets. Isn't this one of the most interesting captions you've ever read? Anyway, this plant printed and dye cut about a hundred grand of those little cardboard school desks.

8. Even containers need containers. A young lady who Thrasher denies he promised "to make a star" loads finished album jackets into boxes for shipment to the record pressing plant where they will be mated with their albums.

From inception to completion, the packaging required approximately two months of preparation and production. It took Ivy Hill about three and a half weeks after they got finished artwork to run off the critters.

These two pictures are a simulated enactment of what the folks at the pressing plant had to do with each and every School's Out album. The imitation album stuffing lady is pulling up an actual pair of panties on an actual Alice Cooper album. Just thought you'd like to know what it probably looked like.